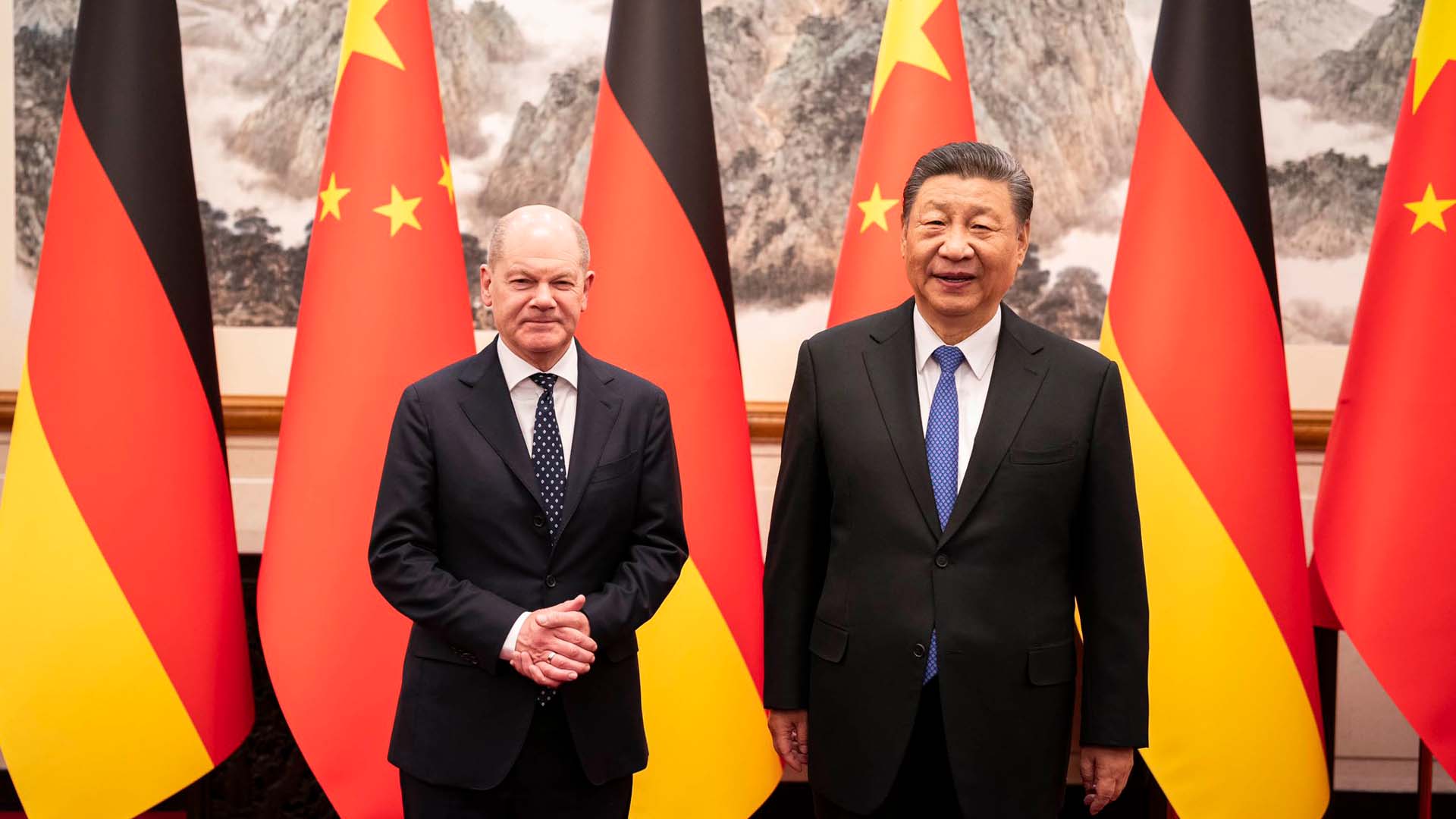

Chancellor Scholz’s Visit to China: Strengthening Economic Ties or Dissatisfying Allies?

German Chancellor Olaf Scholz recently traveled to China for a three-day visit aimed at strengthening economic ties between the two countries. Despite tensions, Germany holds the status of being China’s…

The Bloomberg Billionaires Index: An Accurate and Up-to-date Ranking of the World’s Richest Individuals

The Bloomberg Billionaires Index is a comprehensive ranking of the world’s richest individuals, offering a detailed analysis of their net worth. Each billionaire profile includes a detailed calculation of how…

SCHEELS Honors Iowa High School Athletes for Swimming and Diving: Nominees Announced for Boys Athlete of the Year

The Iowa High School Sports Awards, presented by SCHEELS, have announced the nominees for the Boys Swimming and Diving Athlete of the Year. The winner will be revealed during a…

DOE Report Calls for Advanced Grid Solutions to Meet Biden’s Industrial and Climate Policies

President Joe Biden’s industrial and climate policies are set to drive a significant expansion in power demand into the 2030s. The growing adoption of electric vehicles, the establishment of factories…

Montgomery County Hosts Free Health Fair in Grady: Nutrition, Wellness and Education for All

Montgomery County is set to host a free health fair on Saturday, where approximately 15 vendors will be present to provide information on nutrition and wellness. The event will take…

Revolutionizing Road Safety: AI Drowsiness Detection Tested on Real Drivers

In the driving simulator of a Group, an Audi TT car surrounded by a curved screen, twenty drivers participated in a monotonous driving task of following a car on a…

Private Equity and Venture Capital Ownership in Health-Care: How Private Equity and Venture Capital-Backed Firms Contributed to 2023’s Record Year of Large Health-Care Bankruptcies

A new report from a health-care advocacy group has revealed that private equity-owned businesses were responsible for a significant number of bankruptcies in the industry last year. According to the…

Tesla’s Organizational Overhaul: Embracing Change for Growth and Innovation

Tesla CEO Elon Musk has announced that the company requires a complete organizational overhaul every “half decade or so” in order to maintain growth and innovation. This was recently put…

E-Readers, Windows on Arm, and the Undersea Network: Exploring the Future of Technology

E-readers continue to evolve, and it’s always fascinating to learn about the latest developments in this technology. In this episode, we sit down with The Verge’s Tom Warren and Joanna…

JPMorgan Looks to Fill Key Technology Role in Hong Kong Amidst Flat Equities Sales and Trading Revenues

JPMorgan is currently seeking a new technology managing director in Hong Kong, despite the fact that US banks may be cutting investment bankers in the region. Steve Brooks, who was…